DENBA thawing verification data

Supermarket 65 Stores, Processing Plant Owner

The fundamental problem on defrost

There was a problem when 250 to 300 Kg of frozen meats were sent to flaker while the inner core is still frozen.

After introducing DENBA + thawing machine

The temperature difference between surface and core finally became balanced.The most important benefits of this system is the similar temperature. Therefore, the meats went into the flaker nicely.

DENBA+ reduces drip during defrost

By reducing dripping, the nutrition are not lost。

Company's reaction to DENBA+ Freezing

When DENBA+ was first introduced, people were being skeptical. However, as the result presented itself, where drips were reduced, and the temperature differences between surface and core of meats are small, we all agreed that DENBA+ had the best defrost effect.

The future of DENBA+

There are 65 supermarkets that defrost up to 4 Tons of frozen meat daily. By using the electrons to defrost, it has the following effects.

1- Reduce up to 95% of drips!

2- Prevention of taste loss!

3- Reduces costs for cleaning and detergent!

4- No need to purchase costly defrost machine.

5- All achieved by static waves created within a confined space.

Why choose use?

DENBA+ 3 Step System

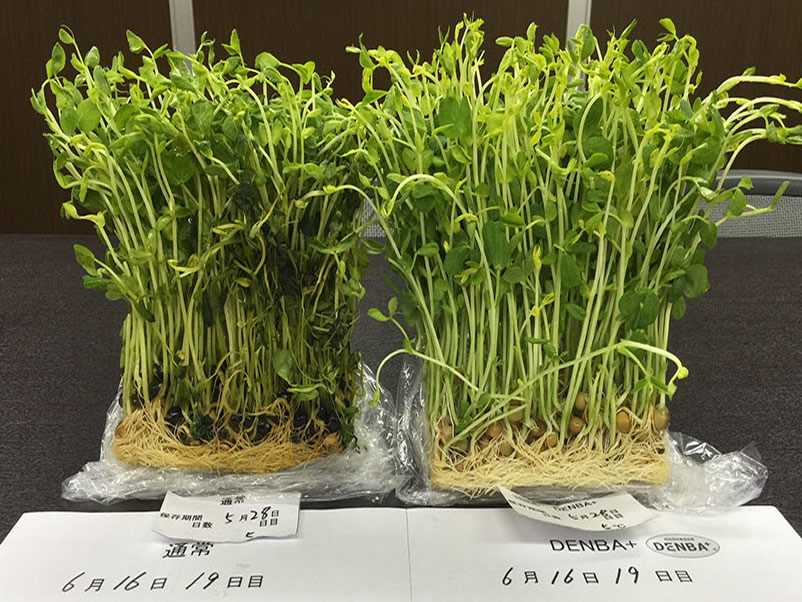

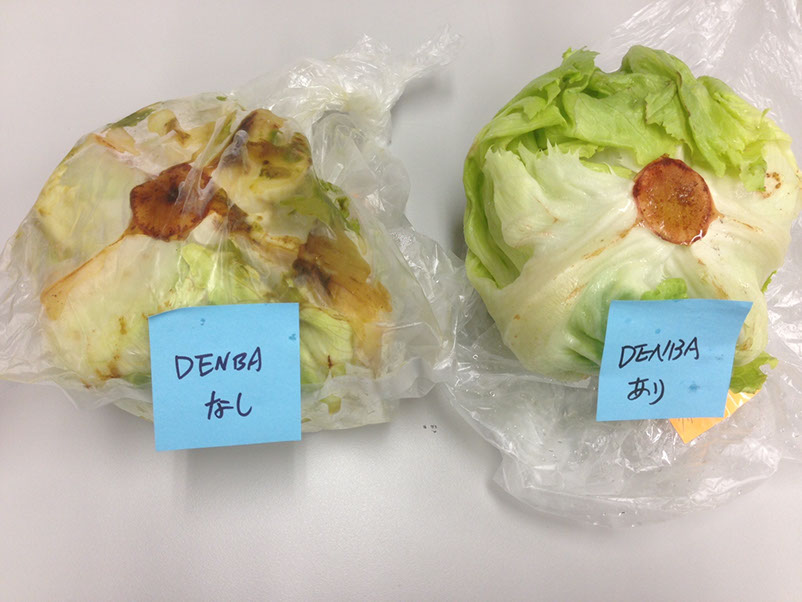

Activated cells maintains freshness

Preserving food under 0 degrees without freezing it, maintaining food freshness.

High quality freezing that doesn't damage cells

Achieve high-quality freezing between -18°C to -25°C.

Unique wavelengths to reduce fluid loss

Reduce up to a maximum of 95% in blood loss. Decrease food loss rate and increase customer satisfaction.

Auxiliary equipment for cooking for fried food

Reducing frying time, improving thermal conductivity, and reduce oil consumption.

Special freshness preservation containers

By installing DENBA in the container, the whole space maintains freshness.

Utilization in medical and health fields

Wide range of utilizations in the health market by downsizing equipment and expanding its applications in the medical field.